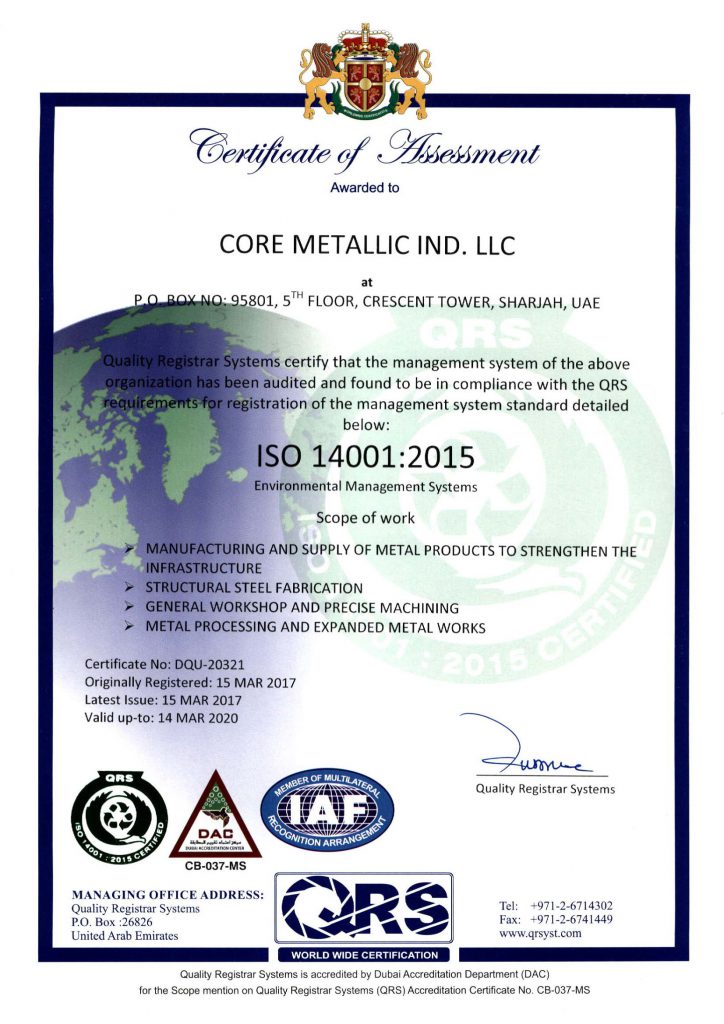

With the escalating growing of the construction industry, coremetal management decided on a policy of horizontal integration to increase the working capability of the company. This move helped to widen the range of products and to compliment the policy of the company to attain maximum customer loyalty through quality and service.

As steel structural works are an integral element of the construction industry, coremetal was inaugurated with specific intentions of achieving self- reliance and widening the scope of services to all important core customer base.

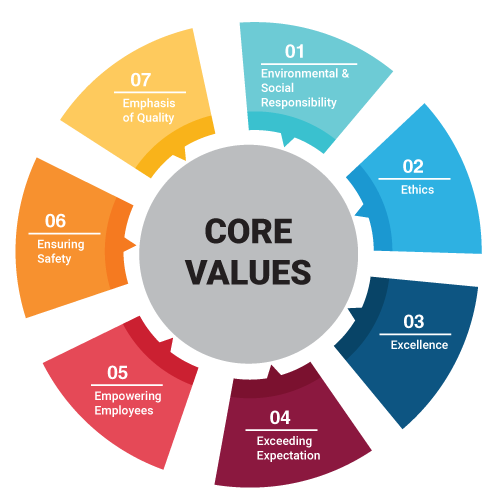

The company operates with the fundamental principle of attaining customer loyalty through quality and service.

To enable the management to achieve this modest goal, a well-equipped plant comprising of latest manufacturing machinery and material handling system was established in Sajja Industrial Area. The professional management set-up comprises of experienced managers, qualified engineers & designers and trained technicians, who adopt most modern manufacturing techniques together with a prudent approach throughout the processes of fabrication and installation of steel structures.

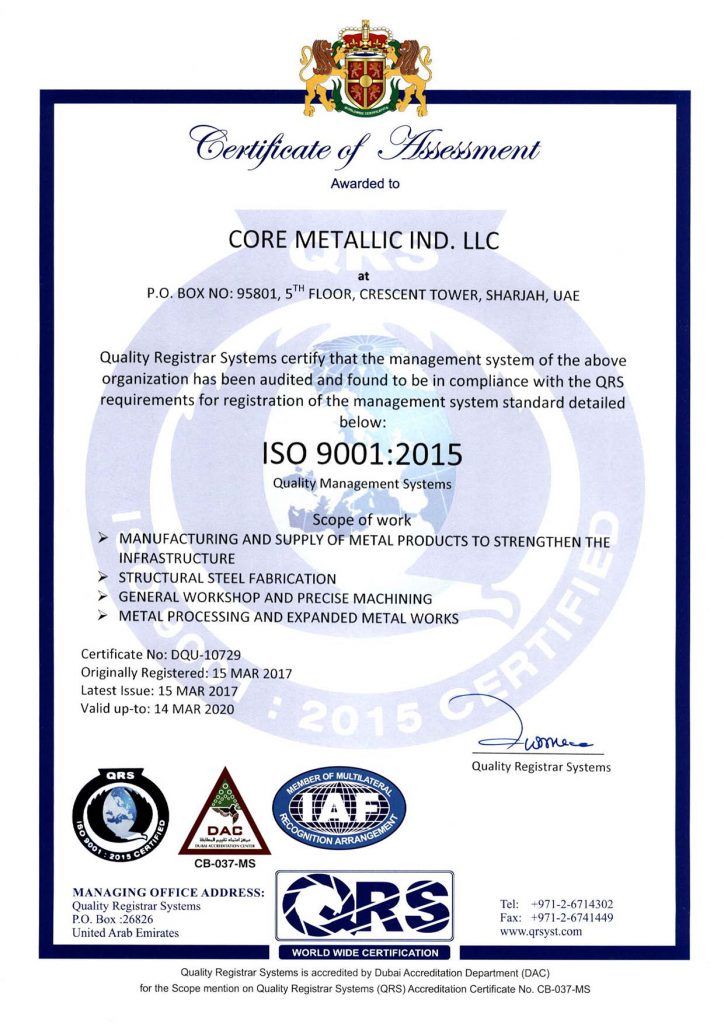

A well-equipped in-house laboratory helps to check the quality of product during the various stages of manufacturing Various testing procedures like MPI, DP, UT and other non-destructive testing techniques are employed according to the project specification requirements. The structural design department, under the supervision of expert structural engineers, develops optimum designs to provide the client with maximum economical benefit without sacrificing the performance and safety aspects of the structures.

A fully computerized design and drafting section was established to help the structural engineering division, to produce drawings.These are useful tools for effective project management.

The company, being a prestigious part of Coremetal Group of Companies, extends the group’s capabilities in every aspect of quality control and timely execution of projects.